A pick list is a list of items, products, or materials that need to be collected or “picked” from a storage location to fulfill orders, restock inventory, or complete production tasks. Picklists are essential for efficient order fulfillment and inventory management processes.

They provide clear instructions to workers on what items to retrieve from storage areas to assemble customer orders or replenish stock. These lists often include information such as item names, quantities, locations, and sometimes additional details like product codes or descriptions.

Let’s uncover how this document works and plays a vital role in shaping the success of online businesses.

A pick list is a document that contains all the instructions for an order needed for shipping the products, like shipment information, item details, and where to find them in the warehouse.

When a customer places an order, the items they’ve selected are compiled into a pick list, which is then provided to the warehouse worker responsible for gathering and packing the items. Warehouse workers use it to get orders ready and send them out safely and efficiently. This process ensures accurate and efficient order fulfillment, helping businesses streamline their operations and meet customer expectations.

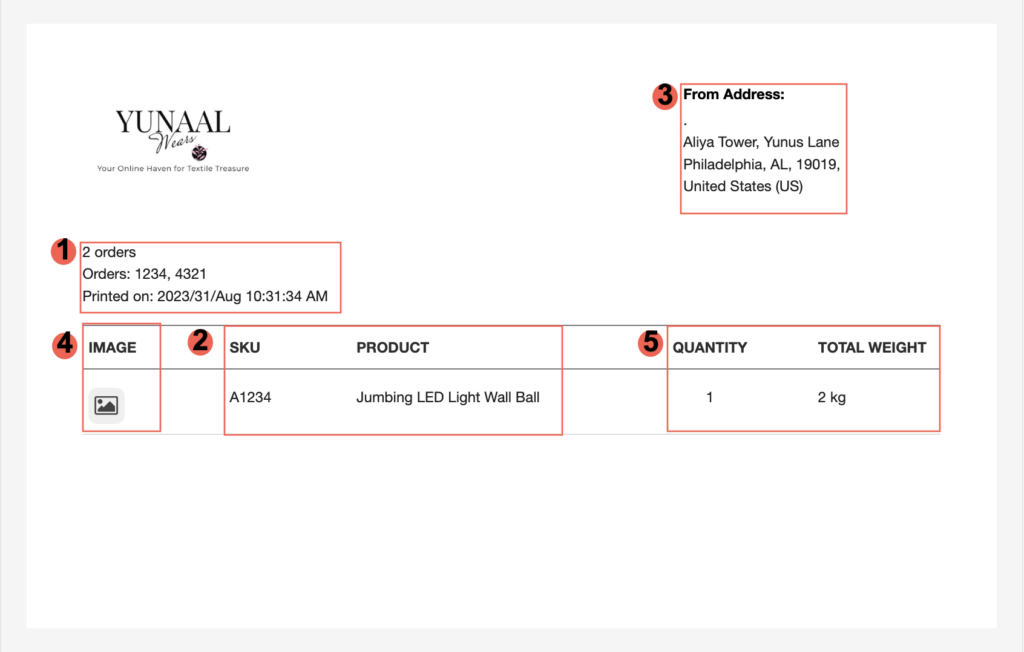

A pick list typically includes the following elements:

- Order Information: This includes details about the specific customer order, such as the order number, customer name, and shipping address.

- Item Details: A list of the items that need to be picked for the order. This includes the product name, SKU (Stock Keeping Unit), and quantity required.

- Warehouse Location: The exact location within the warehouse where each item can be found. This ensures efficient picking and minimizes search time.

- Item Image: An image of each item to help pickers confirm that they are selecting the correct product.

- Quantity and Weight: The quantity of each item that needs to be picked for the order.

These elements collectively help ensure accurate and efficient order fulfillment, minimize errors, and enhance customer satisfaction.

The two main types of pick lists in inventory management are:

Batch Pick List

A batch pick list is a type of pick list where multiple orders with similar or overlapping items are grouped together for picking. Instead of picking items for each order individually, the picker gathers all the required items for multiple orders at once.

This method can save time and reduce the distance traveled within the warehouse, as items for multiple orders can be collected in a single trip. Once the batch is picked, the items are then sorted and separated to fulfill each individual order.

Discrete Pick List

A discrete pick list is a more traditional approach where each order has its own separate pick list. Pickers follow individual pick lists, gathering items for one order at a time. This method ensures that each order is processed independently, which can be particularly useful for maintaining order accuracy and meeting specific customer requirements.

The choice between batch and discrete pick lists depends on factors such as order volume, warehouse layout, item characteristics, and operational efficiency goals. Batch picking is often favored in scenarios with a high volume of orders containing similar items, while discrete picking may be preferred in situations where order customization and accuracy are paramount.

A pick list is necessary for several reasons in the context of e-commerce and inventory management:

Efficient Order Fulfillment: A pick list outlines exactly which items and quantities need to be gathered from the warehouse to fulfill customer orders. This precision ensures that the right products are selected, reducing errors and expediting the fulfillment process.

Streamlined Operations: Pick lists provide a structured and organized approach to order picking. Warehouse personnel can follow the list to navigate the warehouse efficiently, reducing the time and effort required to locate and gather items.

Reduced Fulfillment Errors: With clear instructions and item details, pick lists minimize the chances of mistakes in picking the wrong items or quantities. This leads to improved customer satisfaction by ensuring that customers receive the correct products.

Batch Picking Efficiency: In scenarios with multiple orders, batch pick lists enable picking multiple orders’ items together. This method saves time and reduces unnecessary movement within the warehouse.

In summary, a pick list is necessary to enhance order accuracy, streamline operations, manage inventory effectively, and improve overall efficiency in e-commerce and warehousing environments.

The three common methods for grouping pick lists in warehouse operations are:

Zone Picking

In zone picking, the warehouse is divided into different zones or areas, each assigned to specific pickers. Each picker is responsible for picking items only within their designated zone.

Once all zones are picked, the items are consolidated for packaging and shipping. Zone picking is efficient for larger warehouses and high order volumes, as it reduces picker travel time and increases overall efficiency.

Batch Picking

Batch picking involves picking multiple orders’ items together, often based on similarities in items or their locations. Pickers gather items for multiple orders in a single trip through the warehouse.

After picking, the batch is sorted and divided into individual orders for packaging and shipping. Batch picking is useful when there are many small orders or orders with similar items, as it minimizes travel time within the warehouse.

Pick-to-Order

Pick-to-Order assigns pickers to fulfill individual customer orders. Each picker is given a pick list for a single order, and they gather all the required items for that order. This method ensures order accuracy and is suitable for customized or unique orders, as well as when order sizes vary widely.

Here are some best practices for creating and using pick lists in inventory management and order fulfillment:

Clear and Organized Format: Design pick lists with a clean layout using clear fonts and labels. Organize information logically to help pickers easily understand and follow the list.

Accurate Item Descriptions: Provide accurate and concise descriptions of items to avoid confusion. Include relevant details like color, size, or specifications.

Use Barcodes and Images: Incorporate barcodes and images of items to speed up identification and minimize picking errors. Visual cues help pickers locate items more quickly.

Prioritize and Sequence: If possible, prioritize items based on urgency or grouping. Sequence items logically to guide pickers through the warehouse efficiently.

Digital Pick Lists: Implement digital pick lists through Warehouse Management Systems (WMS) or mobile apps. Digital lists enable real-time updates, reduce paper usage, and enhance accuracy.

Regular List Updates: Keep pick lists up to date with real-time inventory data. Out-of-stock items should be marked clearly to prevent picking errors.

Quality Control Checks: Incorporate quality control checks at different stages of order fulfillment to verify that items match the pick list and customer requirements.

Backup Copies: Have backup copies of pick lists in case of technical issues or unexpected disruptions.

By following these best practices, businesses can optimize their pick list processes, reduce errors, enhance efficiency, and deliver a better overall customer experience.

Conclusion

In eCommerce and inventory management, the pick list emerges as a silent hero, steering the course of seamless order fulfillment. With its ability to guide warehouse personnel through the labyrinth of products, ensure accuracy, and expedite the journey from shelf to shipping, the pick list proves to be an indispensable tool.

By adhering to best practices and embracing the potential of pick lists, businesses can not only save time and reduce errors but also elevate customer satisfaction to new heights. The pick list is undeniably the cornerstone upon which a part of the success of eCommerce fulfillment rests.